Capabilities

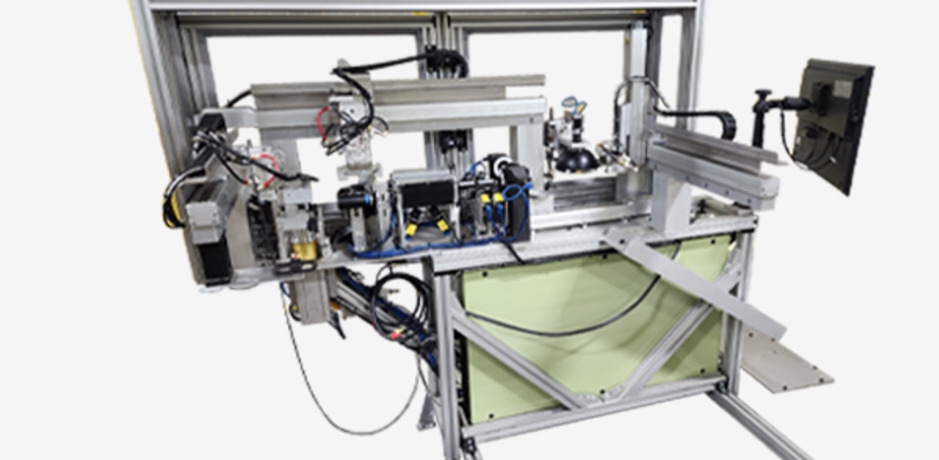

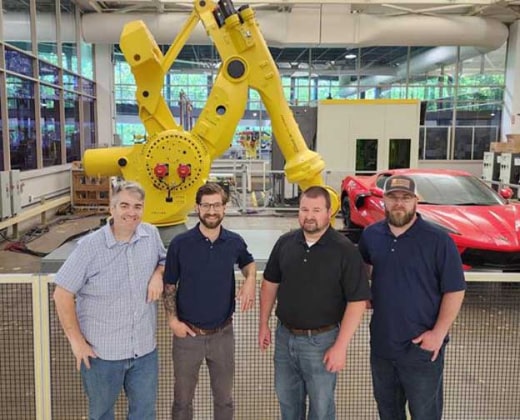

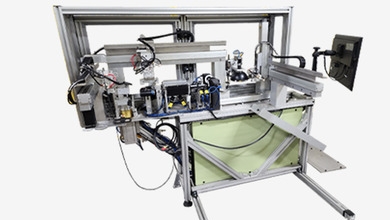

Automated Metrology and Testing

You need to cut costs, improve quality, and do more with less. You look around and see automation opportunities everywhere, but you’re busy running the day-to-day. You’re under tremendous pressure, tired of labor problems, and see advances in automated metrology and testing as key. You may have quality issues and must get human inspection out of the equation or risk losing the customer. Or you have a new project, but reality is now sinking in. Bottom line, you can picture the factory of the future in your mind, but you need a partner with deep competency in automated metrology and test stands, who can manifest your vision while you continue the day-to-day.

Our automated metrology and test stand process starts with a phone call and a visit where we listen, throw around crazy ideas, and ask “what if” together. It’s a lot of fun compared to the daily grind. But we don’t prescribe before diagnosing. We seek to understand the drivers and business results that warrant the investment in a custom system. You want a bespoke custom metrology or test stand solution tailored to your needs, and it must deliver business results on time so you can make a return on your investment. We know it’s not about deploying a particular technology or brand; it’s all about achieving your business goal.

Your crazy idea might work. We exist to Invent Automation. Call, email, or chat with us here and talk to an inventor who gets it, so your automated metrology and test stand solution can get built and you can get that win.

Talk to an Engineer

Talk to an Engineer

"*" indicates required fields

Core Competencies - Automated Metrology and Testing

Automated Non-Destructive Testing

In-Circuit Testing Automation

Precision Measurement Automation

Test Stands

Have Questions?