Custom Automated Machines

Assembly Automation

Talk to an Engineer

Talk to an Engineer

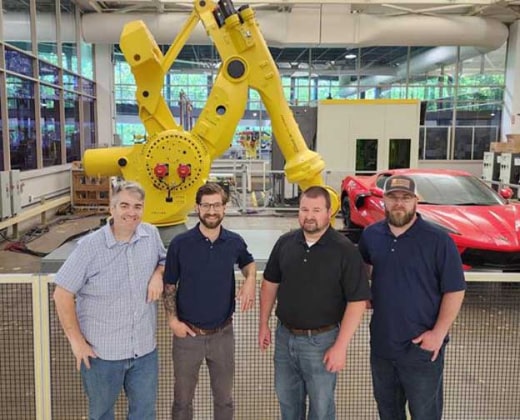

You need a partner who understands the nuances of assembly automation—not someone in their garage and not someone so big that the engineers are hidden behind management and salespeople. Invent Automation is an expert in all things assembly automation. From difficult assembly sequences to unique component integrations, and never forgetting to have the end in mind, we live and breathe this world every day.

You need engineers and inventors knowledgeable in:

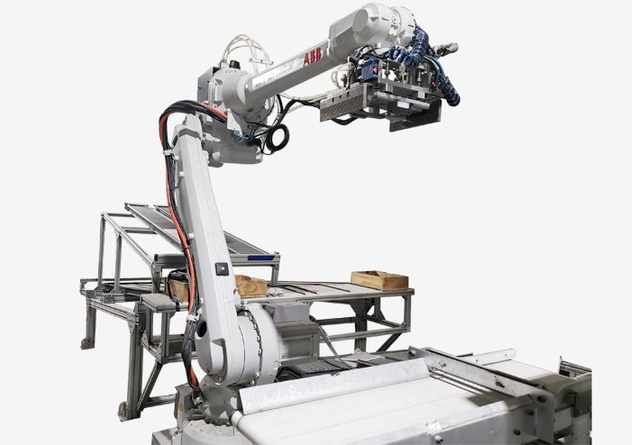

- The myriad ways to handle and sort materials

- Integrating a wide variety of technologies into one system. For example, an assembly machine could include robots, leak testing, component assembly, laser part marking, and machine vision—all in one machine.

- Handling and integrating new technology stacks

- Parts tracking and traceability

- Mistake-proofing the process

Common pitfalls of assembly automation that we ensure you don’t fall into:

- Not having the end in mind

- Encountering bottlenecks that prevent you from making rate

- Choosing the wrong material handling options

We’ve been to hundreds of plants and seen thousands of projects. We’ve rescued failed assembly automation projects, learned from others' mistakes, made some of our own, and know what it takes to make assembly automation machines successful.

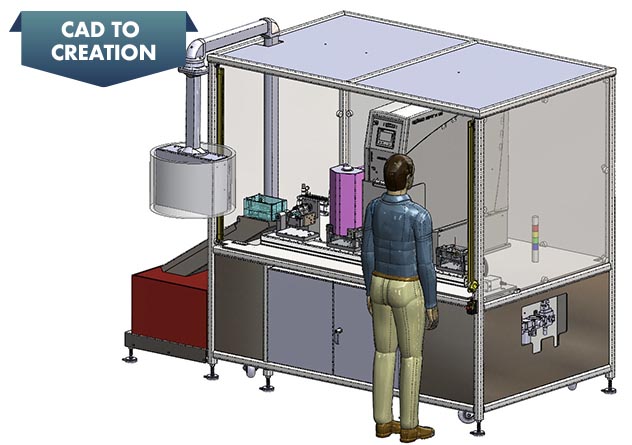

Our custom machine-building process starts with a phone call and a visit where we listen, throw around crazy ideas, and ask “what if” together. It’s a lot of fun compared to the daily grind. But we don’t prescribe before diagnosing. We seek to understand the drivers and business results that warrant the investment in a custom machine. You want a bespoke custom machine tailored to your needs, and it must deliver business results on time so you can make a return on your investment. We know it’s not about deploying a particular technology or brand; it’s all about achieving your business goal.

Your crazy idea might work. We exist to Invent Automation. Call, email, or chat with us here and talk to an inventor who gets it, so your custom machine can get built and you can get that win.

Talk to an Engineer

Talk to an Engineer

"*" indicates required fields

quick roi

Invest in automation

While large-scale assembly plants take time to ramp up, small and medium-sized stations can offer quicker returns on investment. Their lower setup costs and potential for customization allow them to cater to niche markets or handle smaller production runs efficiently.

Try Our ROI CalculatorReduced Costs

Automating repetitive tasks frees up staff and reduces labor needs, leading to lower operational costs.

Improved Accuracy

Machines deliver consistent results, minimizing human error in tasks like data entry or product assembly.

Increased Scalability

Small-scale automation solutions can easily adapt to handle fluctuations in workload without major adjustments.

Freed Up Employees

By tackling repetitive tasks, automation empowers employees to focus on higher-value activities.

- Invent Automation

- Drive Efficiency

- Reduce Labor

- Achieve Excellence

- Revolutionize and Invent Automation

Featured Work - Our Work Defines Us

Automated Pad Printing & Machine Vision Inspection

"Life's too short!"

At a glance

- Automated pad printing

- Machine vision inspection for quality control

- Automatic rejection chute for bad parts

- Simple design for multiple parts