Custom Automated Machines

Small Work Cells

Talk to an Engineer

Talk to an Engineer

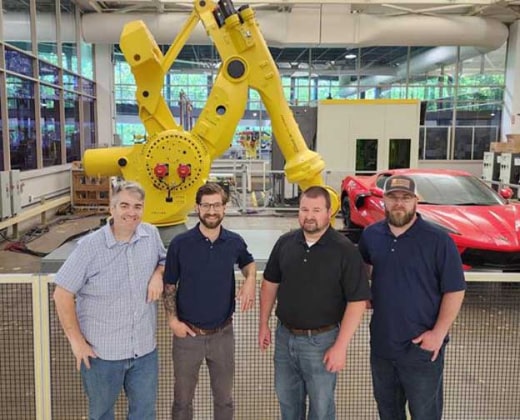

You need a partner who understands how to bring together a small work cell—someone with all the right skillsets under one roof and not someone so big that the engineers are hidden behind management and salespeople. Invent Automation is an expert at making complete small work cells for manufacturers. From U-shaped cells to small production lines, we never forget why you’re doing this, to get more done with less.

You need engineers and inventors knowledgeable in:

- Ergonomic workflows

- Line balancing and breaking down the process

- Integrating a wide variety of technologies into one system.

- Custom small machine design

- Ensuring each station is talking to each other

- Mistake-proofing the process

Common pitfalls of small work cells that we ensure you don’t fall into:

- Not considering the worker demographic

- Not properly balancing the line

- Not accounting for in process calibration and validation

We’ve been to hundreds of plants and seen thousands of projects. We’ve rescued failed work cell projects, learned from others' mistakes, made some of our own, and know what it takes to make a proper work cell successful.

Our custom machine-building process starts with a phone call and a visit where we listen, throw around crazy ideas, and ask “what if” together. It’s a lot of fun compared to the daily grind. But we don’t prescribe before diagnosing. We seek to understand the drivers and business results that warrant the investment in a custom machine. You want a bespoke custom machine tailored to your needs, and it must deliver business results on time so you can make a return on your investment. We know it’s not about deploying a particular technology or brand; it’s all about achieving your business goal.

Your crazy idea might work. We exist to Invent Automation. Call, email, or chat with us here and talk to an inventor who gets it, so your custom machine can get built and you can get that win.

Talk to an Engineer

Talk to an Engineer

"*" indicates required fields

Featured Work - Our Work Defines Us

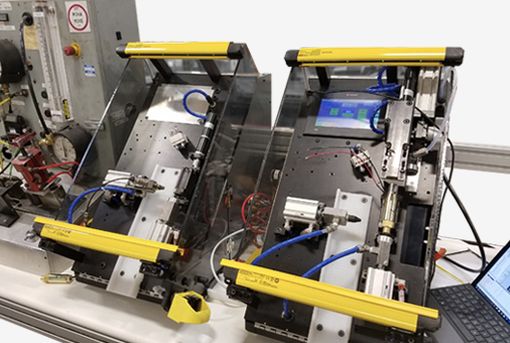

Assembly & Leak Machine Station – Six machines in one!

"Consolidation transforms scattered efforts into power"

At a glance

- What was once six machines is now one

- Labor reduced by 80%

- Two part numbers on one machine

- Leak and flow testing plus assembly all in one!

- Poka-yoked, of course.

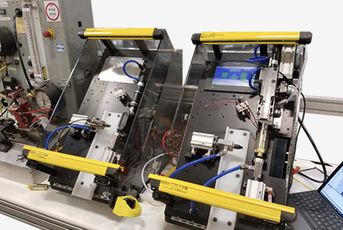

Automated Leak and Flow Tester

"Going with the flow"

At a glance

- Combine four machines into one

- Headcount reduced by 4

- Doubled throughput

- From manual to automated, in 4 months