Impetus to Invent

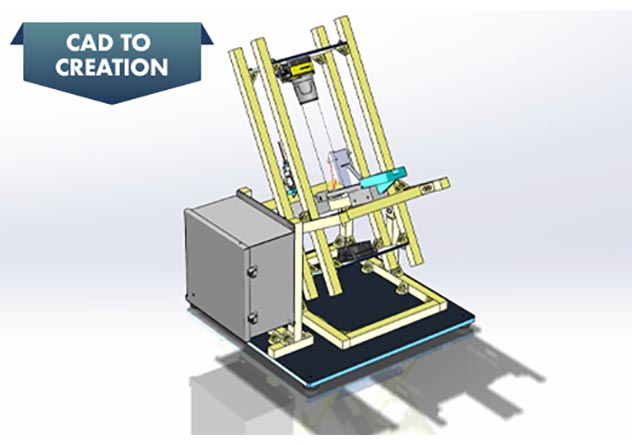

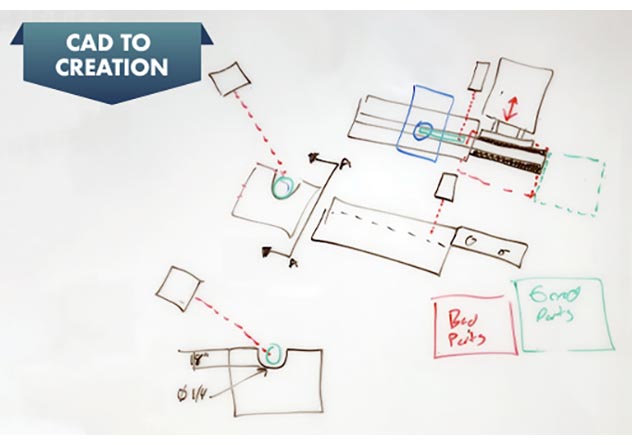

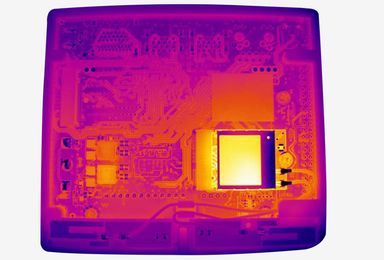

When you have a quality escape to your best customer and the only two options are: remake 3 million parts or find the 100 bad ones, you find a way to locate the bad ones! Invent Automation got the call late one day, thought about it, and the next day started designing and building a solution that could process pins at 50k per day with no errors!

A little 80/20, mix in one Cognex camera, a smattering of 3D printed parts, and plenty of coffee – problem solved. Within a week, the customer was running at full speed and a month later, the problem was behind them. We love our customers, and if they need us to provide a small miracle, we are always up to the challenge. That’s how you build a customer for life.

Problem Solved

With one machine, the operator could feed in parts at a fast rate, and the machine would auto-sort. Good parts would pass through, and bad parts went to the reject bin. A little boring to run, but it’s better than doing it by hand!

Lessons Learned

All machines need a little tweaking and persuading to get started. The angle of the ramp had to be tuned just right so the parts did not go down the chute too fast.

What Was Unique

Did we mention we did this in a week?

What Was Challenging

We reiterate, one week.